_PNG.png)

How do I select the best scanner for my requirements?

Let's first discuss the two main parameters you will need to consider when exploring any scanner for engineering applications- Accuracy and Resolution (AKA - 'Point Spacing')

ACCURACY

If you consider any scanner as throwing thousands to millions of points onto a surface, the scanner's accuracy is the maximum distance those points are allowed to be from the surface of the object. This may be provided as a +/- value or just a number. For example, if a scanner's accuracy is advertised with an accuracy of 10 microns (.00039"), that means if you scan an object, the points captured during the scanning session will not deviate from the true surface by more than 10 microns, on the + or - side of the object.

IMPORTANT - Make certain any scanner you are exploring provides a 'published accuracy'. Many scanners publish their Resolution (aka - Point Spacing') but not the accuracy. The two parameters are very different!

RESOLUTION aka 'POINT SPACING'

While Accuracy is the maximum distance the scanned points (aka 'point cloud') are allowed to be from the true surface, you can consider Resolution as the density of the point cloud. Resolution must be considered, especially when a scanner will be used to capture fine detail of an object. For example, for, scanning a car door, a very low-resolution scanner may be used as there is no fine detail to capture.

Conversely, if scanning something as detailed as a coin, a very high Resolution (i.e. - a very small point spacing) would be required to capture all of the detail on the coin.

If a scanner has a Resolution of 20 microns (.00079"), this means any point captured by the scanner will never be closer to an adjacent point by less than 20 microns.

EXPLORING THE MESH - TRANSITIONING FROM A POINT CLOUD TO A MESH

The vertices get connected with straight line segments to form triangles and the triangular pattern is commonly refered to as a 'Mesh'. Much like 3D Printing, all shapes captured by scanners are ultimately approximations of the shape. The higher the Resolution, the closer the points are to each other, the smaller the triangles are, and more fine detail may be captured.

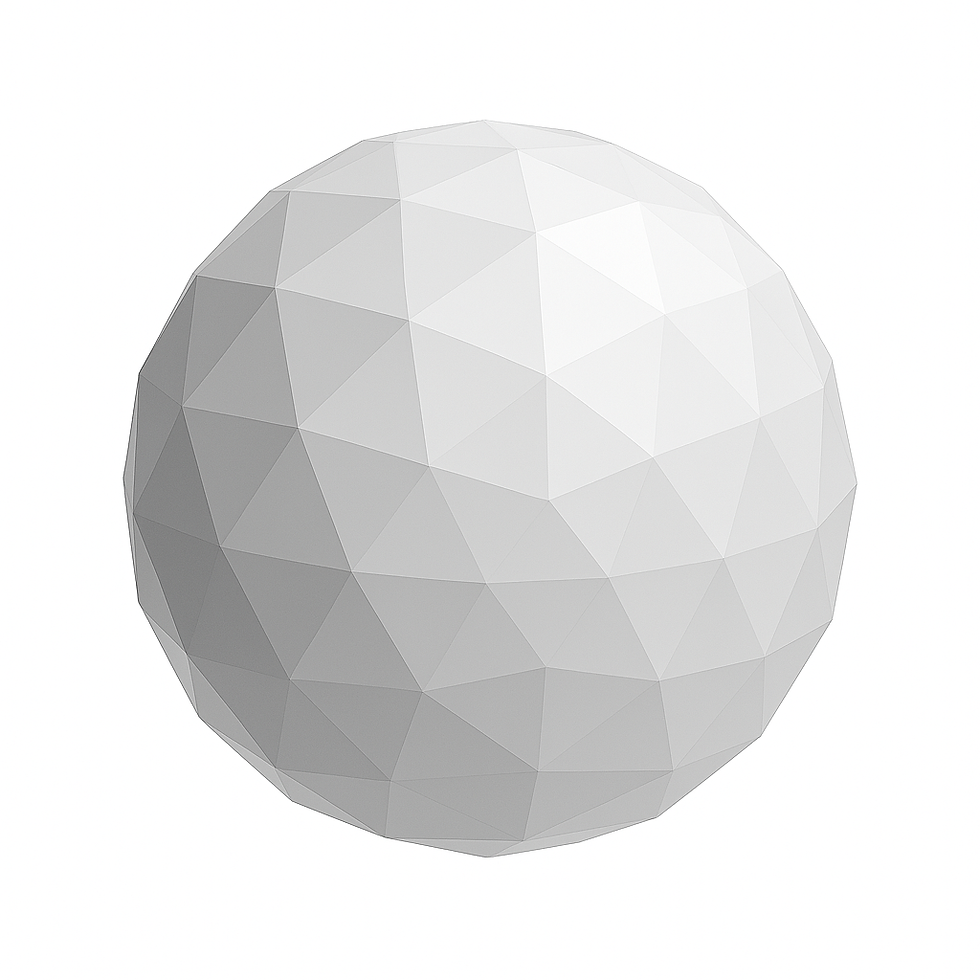

Consider the scan and processed mesh of the sphere below. A low-Resolution sphere will have fewer vertex points and therefore, fewer triangles. If a scan like this were 3D Printed directly from the scan data, the resultant model would look like a faceted disco ball.

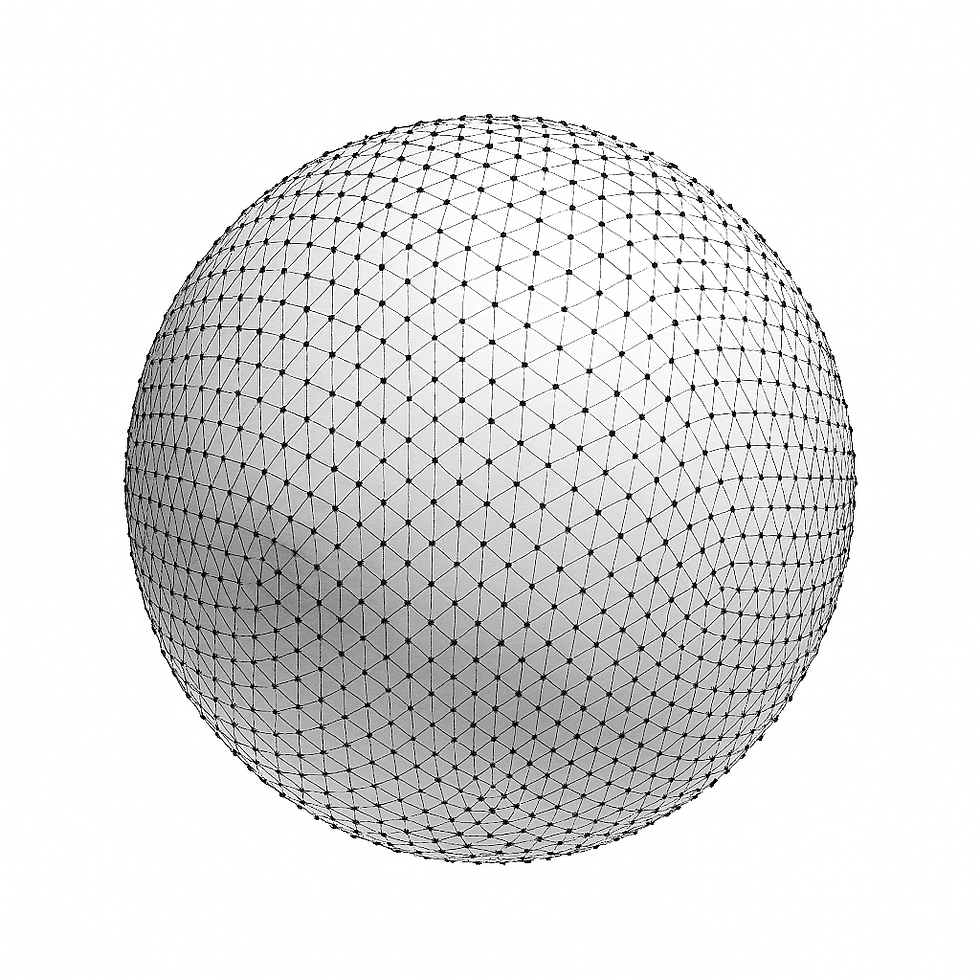

If we now use a higher Resolution scanner, where the Point Spacing is smaller, the point cloud size and density becomes much larger, the triangle size becomes much smaller and the shape of the part looks more like an actual sphere. As the size of each triangle leg approaches 0, the true shape of the sphere is better approximated by the Hi-Resolution scan.

Low-Resolution

Medium Resolution

Hi-Resolution

Very Hi-Resolution

SCANNING FOR INSPECTION VS REVERSE ENGINEERING

As a general rule of thumb, 'ACCURACY' is the more critical parameter when it comes to inspection and 'RESOLUTION' needs to be strongly considered for any reverse engineering application. However, both parameters are critical to successful inspection or reverse engineering.

When performing inspection, a third parameter of 'Repeatability' also needs to be considered. Testing of a scanner to validate its repeatability might include the scanning of the same object several times, performed by several scanner operators, measuring the results as compared to a nominal CAD model and ensuring they are all within an acceptable deviation from each other, for your particular inspection requirements.

For most reverse engineering applications, having an extremely accurate scanner may not be a requirement as the user needs to invoke their own Design Intent knowledge and apply it to the part during the reverse engineering process. This is because when going through a reverse engineering process, the parts/assemblies you are scanning to reverse engineer -

-

Were manufactured, so they aren't dimensionally 'perfect'

-

Are oftentimes 'worn' or used, so they are even less 'perfect'

-

The scanner itself introduces some error into the process